Flow Wrapping Solutions that Create Competitive Advantage

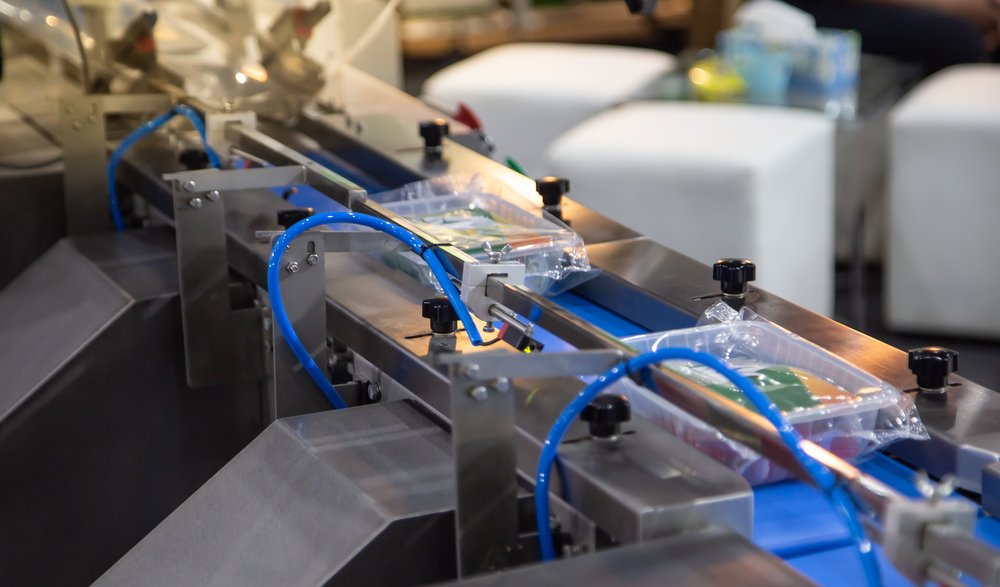

Flow wrapping, also known as horizontal form-fill-seal (HFFS), is a packaging process that involves wrapping products with a flexible material such as plastic, aluminum, or paper, which is then sealed on all sides. This method is highly efficient for producing packages that are secure, attractive, and versatile. Flow wrapping is a highly adaptive packaging technique that supports various industries by offering cost-effective, protective, and attractive packaging solutions. Its ability to maintain the integrity and extend the life of products makes it a popular choice across many sectors.

-

01 Features of Flow Wrapping

- Speed: Flow wrappers can package products at high speeds, often hundreds of packages per minute, making them suitable for large-scale operations.

- Flexibility: The machines can handle a variety of product sizes and shapes, and can quickly switch between different products.

- Material Efficiency: The process uses the exact amount of wrapping material required for each product, minimizing waste.

- Sealing Integrity: Flow wrapping provides strong seals that help protect the contents from contamination, moisture, and tampering.

- Automation: The process is typically fully automated, which reduces labor costs and increases consistency in packaging.

-

02 Benefits of Flow Wrapping

- Product Protection: Offers excellent protection from environmental factors and extends shelf life.

- Cost-Effectiveness: Uses less material and requires less manual labor, which can lead to significant cost savings.

- Consumer Appeal: The final package is neat and attractive, enhancing shelf presence and consumer appeal.

- Versatility: Suitable for a wide range of products, from food items to hardware and pharmaceuticals.

- Sustainability: Reduces waste through efficient use of materials and often uses recyclable materials.

-

03 Different Uses of Flow Wrapping

- Food Industry: Used for packaging snacks, candies, bakery goods, fresh produce, and frozen items. Flow wrapping ensures freshness and hygiene.

- Pharmaceuticals: Used for packaging medical items such as syringes, drug samples, and test kits, where sterility and tamper evidence are crucial.

- Consumer Goods: Used for small items like toys, hardware, electronics accessories, and household goods.

- Cosmetics: Suitable for packaging cosmetic products such as makeup brushes, face masks, and beauty tools.

- Stationery: Flow wraps are also used for pens, pencils, and other small office supplies.

-

04 Environmental Impact and Sustainability of Flow Wrapping

Modern flow wrapping operations are increasingly focused on sustainability by adopting measures designed to minimize environmental impact. These systems aim to enhance efficiency and reduce waste by precisely controlling the amount of wrapping material used, cutting down on excess packaging. To further promote sustainability, there is a significant push towards using eco-friendly materials that are either recyclable or biodegradable, aligning with global environmental standards. Moreover, the integration of energy-efficient machinery, including optimized motors and automated systems, helps decrease the energy consumption of packaging lines. These advancements not only contribute to reducing the carbon footprint of production facilities but also ensure compliance with evolving environmental regulations. By focusing on sustainable practices, the flow wrapping industry is working towards becoming less detrimental to the environment and more aligned with eco-friendly production methods.

Your Gateway to Seamless Flow Wrapping Solutions

CoPack Connect can connect brands with contract packagers that offer Flow Wrapping Solutions. We make it easy for businesses to find the right manufacturer for their needs and provide the tools and resources they need to manage their shock-absorbing packaging projects successfully.

2000+

Manufacturers