Hot Fill Bottling Solutions that Create Competitive Advantage

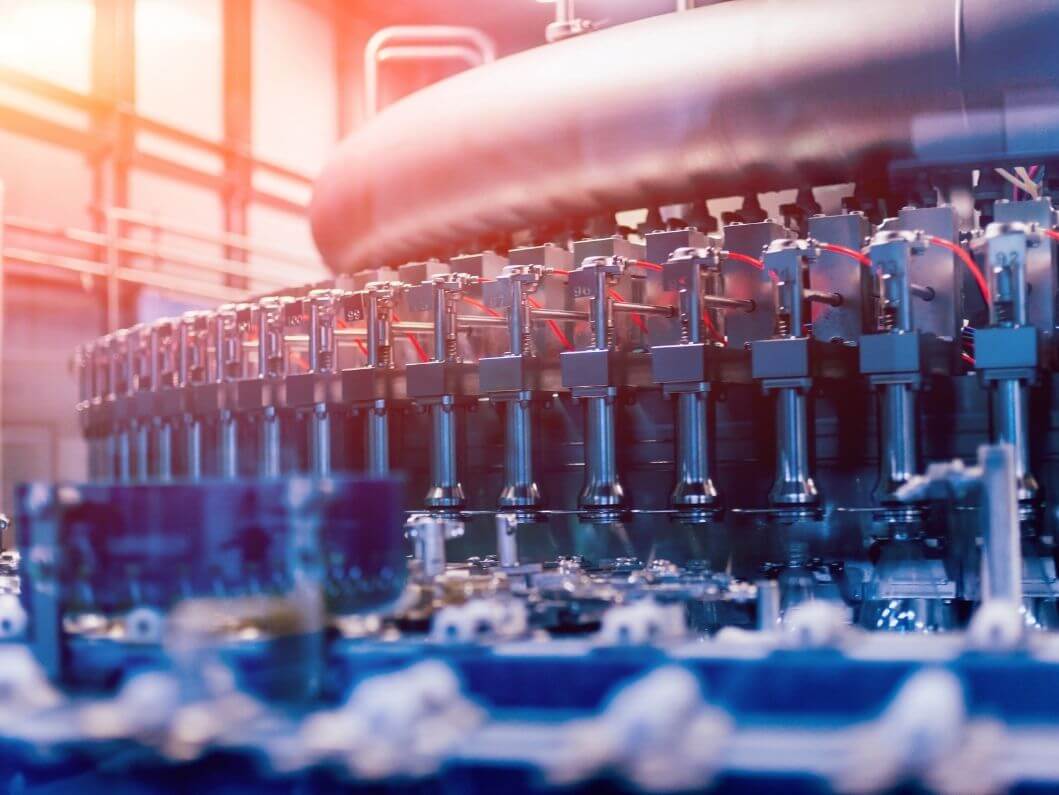

Hot fill bottling is a packaging process widely employed in the food and beverage industry to ensure the safety, longevity, and quality of products without relying on preservatives or refrigeration. This technique involves filling bottles with a product that has been heated to a high temperature to sterilize both the product and the container. The heated product is poured into pre-sanitized containers, such as plastic or glass bottles, which can withstand these high temperatures.

Immediately after filling, the bottles are sealed with airtight caps to prevent contamination. The process of hot fill bottling not only extends the shelf life of products by killing pathogens and spoilage organisms but also helps maintain their taste, nutritional value, and overall quality. By using this method, manufacturers can deliver safe, high-quality products to consumers without the need for artificial preservatives or energy-intensive refrigeration, making hot fill bottling an efficient and cost-effective packaging solution.

-

01 How Hot Fill Bottling Works

The hot fill bottling process begins by heating the product to a temperature typically between 190°F and 205°F (88°C to 96°C). The exact temperature depends on the product’s sensitivity and the pathogens or spoilage organisms likely to be present. This heated product is then poured into pre-sanitized containers, such as plastic or glass bottles, which can withstand high temperatures.

Once the bottles are filled, they are immediately sealed with airtight caps to prevent contamination. The heat from the product serves a dual purpose at this point. It not only helps in killing any remaining bacteria in the product but also sterilizes the headspace (the area between the product and the cap) and the interior surface of the cap. As the product cools down inside the sealed bottle, a vacuum seal forms naturally due to the contraction of the heated air, which further ensures the product’s safety from microbial contamination.

-

02 Hot Fill Bottling by Processing Type

Hot fill bottling can be adapted to different product types, with variations primarily around the product’s sensitivity to heat and its viscosity. For example:

- Juices and Beverages: These are the most common products using hot fill bottling, as the high temperatures do not significantly alter their taste or nutritional value.

- Sauces and Condiments: Products like ketchup, mustard, and barbecue sauce are also well-suited to hot fill bottling. The process helps in maintaining their flavor, texture, and color.

- High-Acid Foods: Foods like tomatoes and certain fruits that have high natural acidity are particularly suitable for hot fill processes because the acid and the heat combine to effectively control microbial growth.

-

03 Benefits of Hot Fill Bottling

Hot fill bottling offers several advantages:

- Extended Shelf Life: By eliminating spoilage organisms and creating a vacuum seal, the shelf life of products is significantly extended without refrigeration.

- Product Integrity: The process maintains the nutritional and sensory properties of the product, as it minimizes the need for additives and preservatives.

- Cost-Effectiveness: Hot fill bottling reduces the need for cold chain logistics and storage, which can be cost-prohibitive.

- Safety: The sterilization effect of high temperatures ensures that the products are safe from foodborne pathogens.

- Eco-Friendly: This process can be more environmentally friendly as it reduces the reliance on preservatives and energy-intensive refrigeration.

-

04 Examples of Hot Fill Bottling Applications

Various products leverage hot fill bottling to maximize their quality and shelf life. Some common examples include:

- Fruit Juices: Many fruit juices are hot-filled to maintain taste and prevent fermentation or spoilage.

- Teas and Coffees: Ready-to-drink teas and coffees use hot fill bottling to preserve freshness and flavor.

- Sports Drinks: These beverages are often acidic and benefit from hot fill bottling to maintain their efficacy and flavor over time.

- Nutritional Drinks: Liquid nutritional supplements are typically sensitive to microbial contamination and benefit greatly from the hot fill process.

Your Gateway to Seamless Hot Fill Bottling Solutions

CoPack Connect can connect brands with contract manufacturers and packagers that offer hot fill bottling services. We make it easy for businesses to find the right manufacturer for their needs and provide the tools and resources they need to manage their hot fill bottling projects successfully.

2000+

Manufacturers