Contract Packaging

Blister Trays

Blister Trays Solutions that Create Competitive Advantage

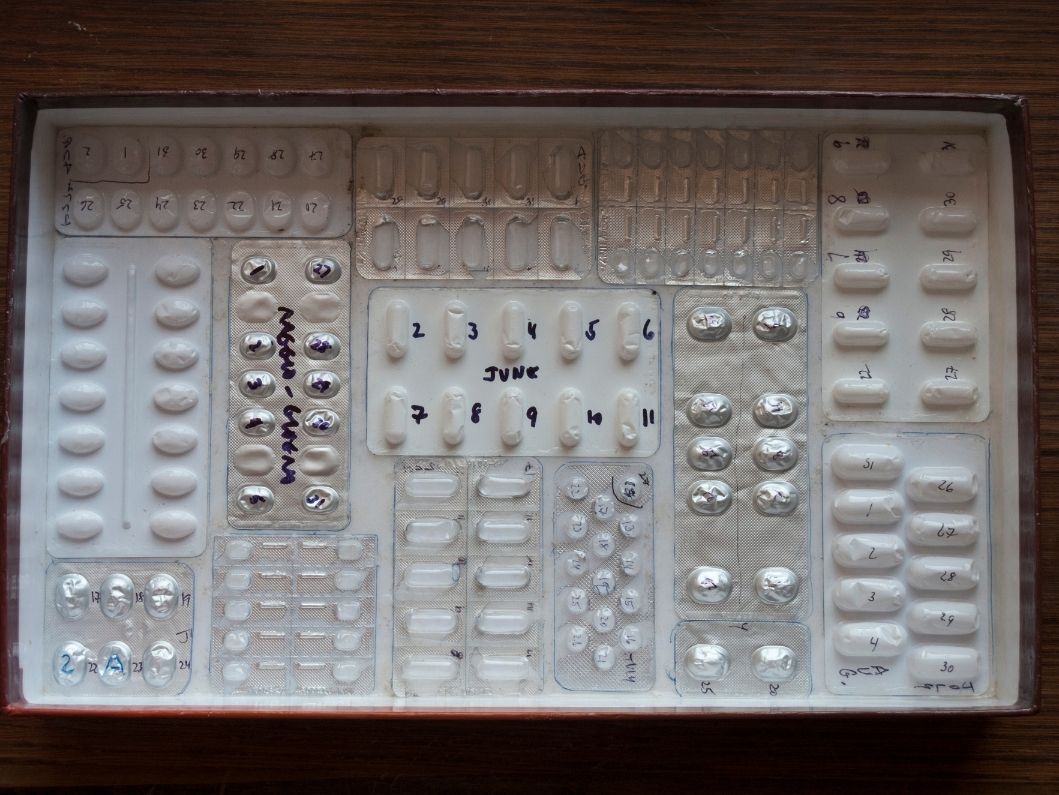

Blister trays are a type of packaging designed to securely encase and protect individual products within separate, molded compartments. These trays are often paired with a clear plastic cover or backing, providing visibility of the product while ensuring it remains protected from damage, contamination, or tampering. Available in various configurations, blister trays can be customized to accommodate different shapes, sizes, and weights, making them an ideal choice for a range of industries. Standard blister trays are sealed with backing materials like paperboard or foil, while high-end versions may include tamper-evident features, re-sealable properties, or enhanced protective layers.

-

01 Types of Blister Trays

- Standard Blister Trays: Simple, single-use trays designed to hold products securely and prevent movement or damage. Often paired with a heat-sealed backing.

- Slide Blister Trays: Feature a sliding mechanism, typically with a card that can be pulled out, making it easy for consumers to access the product while keeping it protected when not in use.

- Clamshell Blister Trays: A more durable and reusable option, with a hinge that allows the tray to open and close. These are often used for electronics and heavier products.

- Combination Blister Trays: Used for multi-product packaging, where each item has its own compartment, ensuring complete protection for each piece.

-

02 Features of Blister Trays

- Material: Often made from clear, rigid plastics like PVC or PET, which offer high visibility and excellent product protection.

- Design: Molded to the specific shape of the product to ensure a snug fit, preventing movement and damage.

- Customizability: Can be tailored to fit any product shape or size, with the option for tamper-evident seals, re-sealable options, or enhanced protective barriers.

- Visibility: The clear plastic design allows consumers to see the product without opening the package, enhancing product appeal.

- Tamper-Evidence: Many blister trays include tamper-evident seals, ensuring the product’s integrity remains intact from manufacturing to the end user.

-

03 Benefits of Blister Trays

- Product Protection: Blister trays offer excellent protection against impact, contamination, and tampering, ensuring products remain in perfect condition.

- Clear Presentation: The transparent design provides full product visibility, making it easy for consumers to inspect items before purchase.

- Custom Fit: The molded design ensures a secure fit, reducing the risk of movement or damage during shipping or handling.

- Space Efficiency: Blister trays are stackable and take up less space during transport, making them a practical solution for manufacturers.

- Branding Opportunities: The backing material can be printed with logos, product information, and marketing messages, turning the packaging into an additional branding tool.

-

04 Different Uses of Blister Trays

- Pharmaceuticals: Widely used for packaging pills, capsules, and other medications. Blister trays protect individual doses from contamination and provide easy access for patients.

- Consumer Electronics: Perfect for small electronics like headphones, chargers, or memory cards, keeping them secure and well-protected.

- Toys and Collectibles: Frequently used in the toy industry to package figurines and small parts, ensuring they remain organized and undamaged.

- Hardware: Handy for packaging screws, nails, and small tools, blister trays keep everything organized while preventing loss or damage.

- Cosmetics: Popular for packaging single-use skincare products, small beauty tools, and sample sizes of makeup.

-

05 Environmental Impact and Sustainability of Blister Trays

As the demand for eco-friendly packaging grows, manufacturers are adopting more sustainable materials for blister trays. Recyclable plastics like PET are becoming more common, and some manufacturers are moving toward biodegradable options. Lightweight yet durable, blister trays also help reduce transportation emissions by optimizing space efficiency and reducing packaging waste. Advances in production techniques have also minimized material waste during the manufacturing process, aligning blister trays with modern sustainability goals.

Your Gateway to Blister Tray Solutions

CoPack Connect can connect brands with contract packagers that offer blister tray services. We make it easy for businesses to find the right manufacturer for their needs and provide the tools and resources they need to manage their blister tray projects successfully.

2000+

Manufacturers