Contract Packaging

Dry Box Filling

Dry box filling is an important process in numerous industries, particularly those that handle hygroscopic materials, delicate electronics, pharmaceuticals, and other products susceptible to moisture. This process needs a controlled environment, often with reduced humidity, to ensure the quality, integrity, and longevity of the products. With dry box filling contract packaging, brands can achieve precision and consistency without the need for substantial investment in niche equipment and infrastructure.

-

01 Features of Dry Box Filling

- Controlled Environment: Dry boxes maintain a specific range of humidity and temperature, crucial for protecting sensitive items.

- Sealable and Secure: These boxes are designed to be airtight and moisture-proof, often with gaskets or other sealing mechanisms.

- Durable Materials: Typically made from robust materials like stainless steel or high-grade plastics that resist corrosion and wear.

- Desiccant Integration: Many dry boxes include desiccants, materials that absorb moisture, to ensure a dry environment.

-

02 Benefits of Dry Box Filling

- Protection Against Moisture: Critical for items that are sensitive to humidity or prone to rust, mold, and other moisture-related damage.

- Long-Term Storage: Offers an optimal solution for storing items over long periods without degradation.

- Maintains Product Integrity: Ensures that products remain in their original condition, preserving functionality and appearance.

- Versatility: Can be used for a wide range of items, from industrial goods to sensitive electronics.

-

03 Different Uses of Dry Box Filling

- Electronics and Semiconductor Industries: Used to store and transport sensitive components like circuit boards and chips that can be damaged by static electricity and moisture.

- Pharmaceuticals: Essential for drugs and biological materials that require dry conditions to maintain efficacy and shelf life.

- Photographic and Optical Equipment: Protects cameras, lenses, and other equipment from fungal growth and condensation.

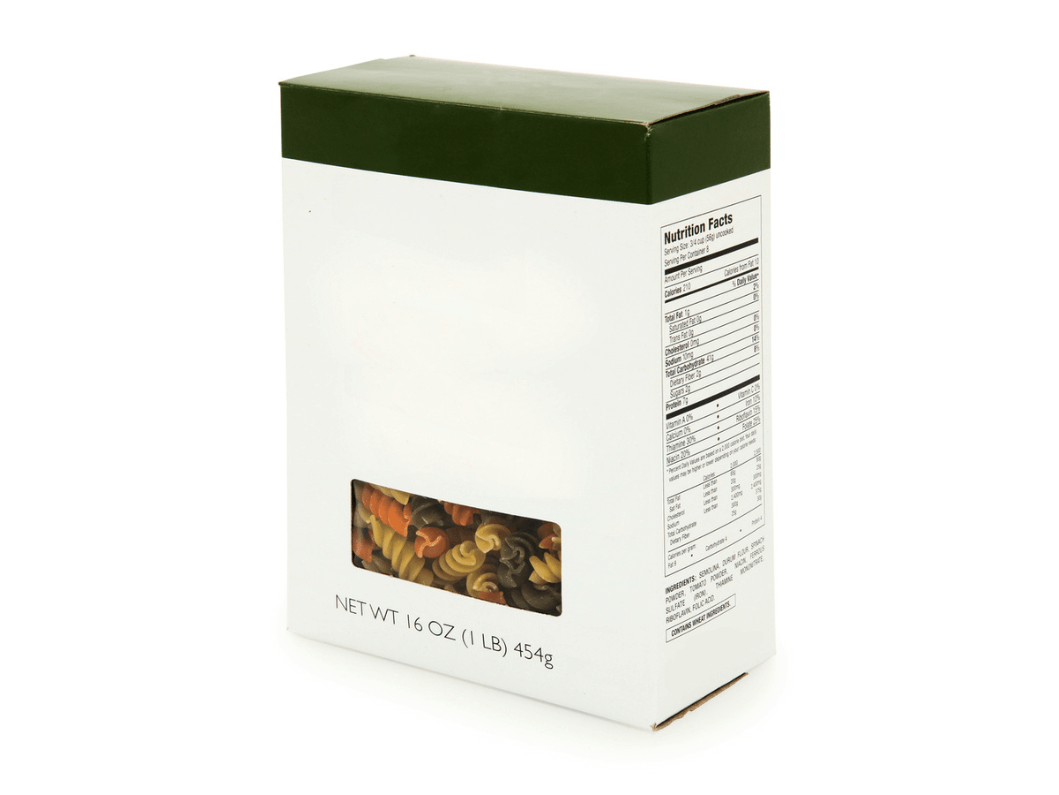

- Food Industry: Used for keeping dry foods like powders, spices, and grains free from moisture, thus preventing spoilage.

- Cultural and Historical Preservation: Ideal for storing archival materials, artworks, and artifacts that are sensitive to environmental conditions.

- Outdoor and Field Use: Helpful for researchers and professionals working in moist or marine environments to keep equipment and samples dry.

-

04 Environmental Impact and Sustainability of Dry Box Filling

In dry box filling, sustainability and environmental responsibility are increasingly prioritized. Modern systems feature advanced sealing and insulation to maintain stable internal conditions with minimal power usage, enhancing energy efficiency. There’s a shift towards using sustainable, recyclable, or biodegradable materials in construction, promoting waste reduction and a circular economy. Durably designed dry boxes minimize the need for frequent replacements, reducing material waste.

Compliance with strict environmental regulations ensures the use of non-toxic materials and promotes recycling efforts. Innovations in natural or biodegradable desiccants that absorb moisture effectively without harming the environment also contribute to sustainability. These initiatives collectively improve compliance with global environmental standards and establish dry box filling as an environmentally responsible choice for industries requiring precise moisture control.

Your Gateway to Seamless Dry Box Filling Solutions

CoPack Connect can connect brands with contract packagers that offer dry box filling services. We make it easy for businesses to find the right manufacturer for their needs and provide the tools and resources they need to manage their dry box filling projects successfully.

2000+

Manufacturers