Contract Packaging

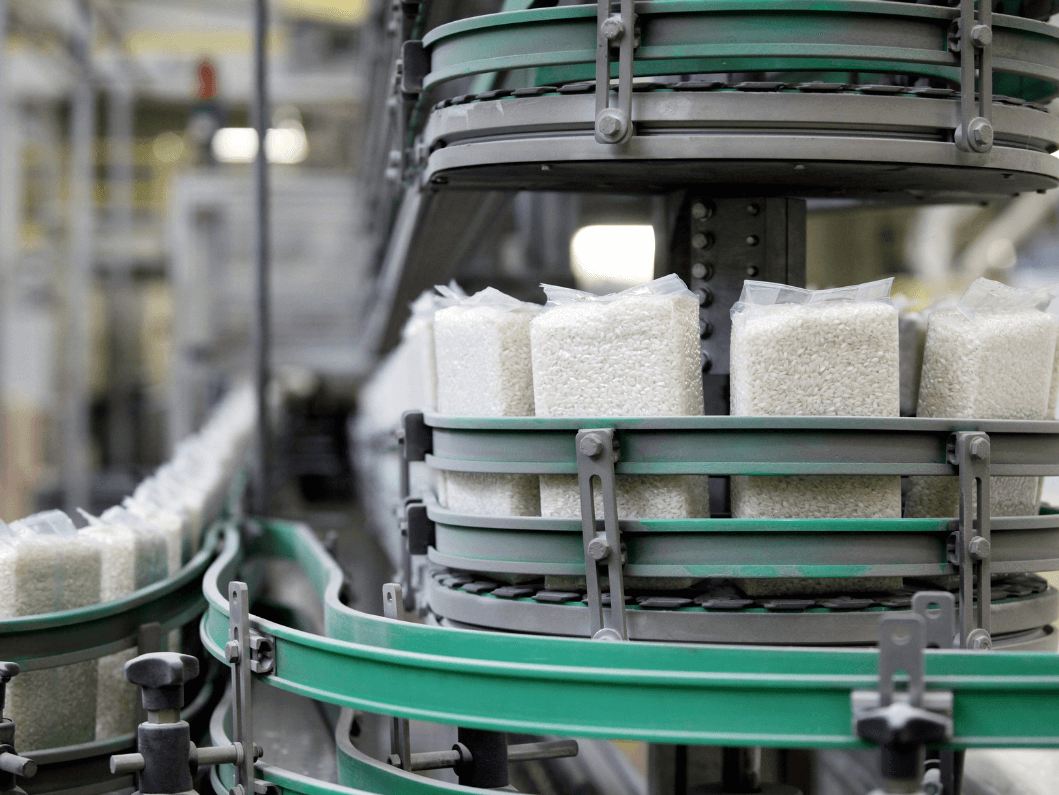

Dry Pouch Filling

Dry pouch filling is a service that involves the packaging of various dry products into pouches. This method of packaging offers numerous benefits, such as extended shelf life, convenience, and cost-effectiveness. With the help of advanced machines and technology, dry pouch filling has become a popular choice for both manufacturers and consumers. Its ability to extend shelf life, convenience, and cost-effectiveness make it a popular choice for both manufacturers and consumers. With advancements in technology, the process of dry pouch filling has become more automated and streamlined, ensuring consistent quality and efficiency. As the demand for convenient and sustainable packaging options continues to grow, dry pouch filling is likely to remain a preferred choice for various industries.

-

01 Benefits of Dry Pouch Filling

- Preservation and Protection: Dry pouch filling helps in preserving the quality and extending the shelf life of products by providing an airtight environment that protects against moisture, contaminants, and other environmental factors.

- Convenience: Pouches are lightweight, portable, and user-friendly, making them a convenient option for consumers. They often feature easy-open and resealable options.

- Cost-Effectiveness: Compared to rigid packaging solutions, pouches generally require less material and are cheaper to produce and transport.

- Sustainability: Many pouch materials are designed to be more sustainable, using less plastic and being more efficient to transport than traditional packaging methods.

-

02 Features of Dry Pouch Filling Machines

- Versatility: Machines can handle a wide range of pouch sizes and types, including stand-up pouches, flat pouches, and more.

- Automation: Modern dry pouch filling systems are typically automated, which enhances efficiency, accuracy, and consistency in filling operations.

- Speed: High-speed filling options allow for large volumes of products to be packaged quickly.

- Integrated Systems: Many machines come with integrated weighing and sealing systems, which streamline the packaging process.

-

03 Different Uses of Dry Pouch Filling

- Food Industry: Commonly used for packaging spices, snacks, coffee, tea, dried fruits, and cereals.

- Pharmaceuticals: Used for packaging powdered drugs, supplements, and other medical supplies.

- Agricultural Products: Suitable for seeds, fertilizers, and other agricultural inputs.

- Chemicals: Often used for packaging small quantities of dry chemicals used in various industrial processes.

-

04 Environmental Impact and Sustainability of Dry Pouch Filling

Dry pouch filling operations are increasingly adopting eco-friendly practices to enhance sustainability and reduce environmental impact. These systems focus on precision in the filling process to minimize spillage and waste, optimizing the use of resources. With an emphasis on sustainability, there is a significant shift towards using biodegradable and recyclable materials for pouches, supporting global environmental conservation goals. Additionally, the integration of energy-efficient technologies in dry pouch filling systems, such as high-efficiency motors and automated processes, reduces energy consumption across production lines. These initiatives not only help in decreasing the ecological footprint of manufacturing operations but also ensure adherence to stringent environmental regulations, contributing to a more sustainable and environmentally responsible industry.

Your Gateway to Seamless Dry Pouch Filling Solutions

CoPack Connect can connect brands with contract packagers that offer dry pouch filling services. We make it easy for businesses to find the right manufacturer for their needs and provide the tools and resources they need to manage their dry pouch filling projects successfully.

2000+

Manufacturers