Flat Bottom Pouches Solutions that Create Competitive Advantage

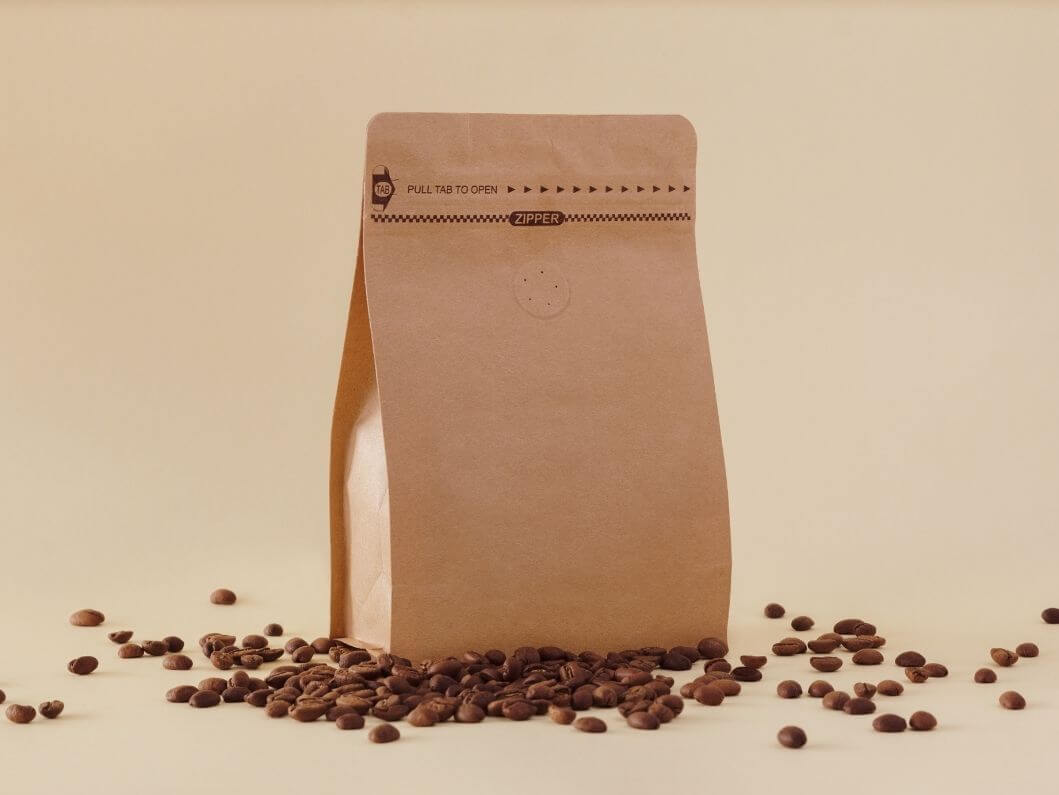

Flat Bottom Pouches stand out as a versatile and innovative packaging solution, particularly favored for their stable, self-standing design. These pouches combine the best features of stand-up pouches and traditional boxes, offering a practical yet visually appealing packaging option. Available in various types, these pouches are designed to meet diverse packaging requirements. The standard flat bottom pouch provides a sturdy base, making it ideal for products that need to stand upright on store shelves. The gusseted version offers additional space, perfect for bulkier items. Resealable flat bottom pouches feature zip-lock closures, ensuring product freshness and extended shelf life, while vacuum-sealed types are designed for perishable goods, preserving freshness and extending product longevity. Each type can be customized in terms of size, material, and design, catering to a wide range of industries.

-

01 Features of Flat Bottom Pouches

- Design and Structure: The defining feature of flat bottom pouches is their ability to stand upright, thanks to the flat base and gusseted sides. This structure not only enhances the pouch’s stability but also maximizes storage capacity.

- Material Composition: These pouches are crafted from various flexible materials, including plastic films, foils, and multi-layer laminates. This material versatility allows for excellent barrier properties, protecting products from moisture, oxygen, and light.

- Sealing Options: Flat bottom pouches typically feature resealable zippers, tear notches, and heat-sealed edges. The resealable option is particularly beneficial for products that are consumed over time, ensuring freshness.

- Customization Potential: The broad, flat surfaces of these pouches offer ample space for branding and product information. They can be easily customized with high-quality printing, making them a strong marketing tool.

- Size and Capacity: Flat bottom pouches come in various sizes and can be tailored to fit specific products, from small snack packs to large bulk items.

-

02 Benefits of Flat Bottom Pouches

- Enhanced Shelf Presence: The ability of flat bottom pouches to stand upright provides an excellent display on store shelves, increasing product visibility and consumer appeal.

- Efficient Storage and Transport: These pouches are designed to be space-efficient, both in storage and transport. Their stackable design reduces the amount of space required, optimizing logistics and reducing costs.

- Versatility: Flat bottom pouches are suitable for a wide range of products, from food and beverages to pet food, health supplements, and household goods. Their flexible design allows for use across multiple industries.

- Durability and Protection: The multi-layered materials used in flat bottom pouches provide robust protection against external factors such as moisture, air, and light, which are crucial for maintaining product quality.

- Sustainability: Many flat bottom pouches are now made from recyclable or biodegradable materials, reflecting the industry’s shift towards more sustainable packaging solutions. Their lightweight nature also contributes to reduced transportation emissions, aligning with environmental standards.

-

03 Different Uses of Flat Bottom Pouches

- Food and Beverage Industry: These pouches are widely used for packaging coffee, tea, nuts, cereals, snacks, pet food, and powdered products. Their ability to preserve freshness and extend shelf life makes them a popular choice.

- Health and Beauty: Ideal for packaging products such as bath salts, protein powders, and other health supplements, flat bottom pouches offer convenience and product protection.

- Household and Industrial Products: From detergents to fertilizers, flat bottom pouches are used to package a wide range of household and industrial products, providing durability and ease of use.

- Pet Food: These pouches are particularly favored in the pet food industry for their ability to store and preserve large quantities of dry or wet food, with the added benefit of resealability for ongoing use.

-

04 Environmental Impact and Sustainability of Flat Bottom Pouches

The shift towards sustainable packaging is evident in the evolution of flat bottom pouches. By utilizing recyclable materials and reducing overall material usage, these pouches contribute to minimizing environmental impact. Their lightweight design not only decreases transportation emissions but also supports global efforts to reduce packaging waste. Additionally, the focus on using biodegradable or eco-friendly materials ensures that flat bottom pouches are a responsible choice for both businesses and consumers, aligning with broader sustainability goals.

Your Gateway to Flat Bottom Pouches Solutions

CoPack Connect can connect brands with contract packagers that offer flat bottom pouches packaging services. We make it easy for businesses to find the right manufacturer for their needs and provide the tools and resources they need to manage their flat bottom pouches packaging projects successfully.

2000+

Manufacturers