Plastic Jars Solutions that Create Competitive Advantage

In the realm of contract manufacturing, one important aspect that cannot be overlooked is the use of plastic jars in food packaging. Plastic jars have become a popular choice for packaging various food products due to their versatility, durability, and cost-effectiveness. They offer a wide range of benefits and are widely used in the food industry consumer and industrial applications.

-

01 Features of Plastic Jars

- Material Varieties: Plastic jars can be made from several types of plastic, including polyethylene terephthalate (PET), high-density polyethylene (HDPE), and polypropylene (PP). Each type offers unique characteristics in terms of clarity, resistance, and chemical compatibility.

- Design Flexibility: They come in various shapes, sizes, and colors, which can be tailored to specific market needs and branding requirements. This includes everything from small, clear jars for cosmetics to large, durable containers for industrial products.

- Seal Integrity: Plastic jars typically have screw-on lids, although other closures like flip-tops or pumps are also common. These closures provide excellent seal integrity to protect contents from moisture, air, and contaminants.

- Lightweight: Compared to glass, plastic jars are much lighter, which can significantly reduce shipping and handling costs. This also makes them easier and safer to handle.

- Durability: They are tough and resistant to breaking, making them ideal for products that require robust packaging for shipping and handling.

-

02 Benefits of Plastic Jars

- Cost-Effective: Plastic jars are generally cheaper to produce than glass or metal containers. This makes them an economical choice for many businesses, particularly for high-volume products.

- Safety: Their resistance to breakage reduces the risk of injury from broken packaging, making them a safer option in environments where breakage is a concern, such as in homes with children or in high-impact industrial settings.

- Energy Efficient: The lightweight nature of plastic jars means that they require less energy to transport, contributing to lower carbon emissions compared to heavier packaging options.

- Recyclability: Many plastic jars are made from materials that can be recycled, which helps in reducing the environmental impact. However, the rate of recycling depends on the local recycling capabilities and regulations.

- Transparency and Aesthetics: Certain types of plastic like PET are highly transparent, allowing for clear visibility

-

03 Different Uses of Plastic Jars

- Food and Beverage: Used for packaging a variety of food items such as jams, jellies, honey, peanut butter, and beverages. Their good chemical resistance makes them suitable for acidic or vinegary foods.

- Cosmetics and Personal Care: Commonly used for products like creams, gels, shampoos, and conditioners. The ability to produce jars in different colors and with various dispensing options makes them ideal for this sector.

- Pharmaceuticals: Plastic jars provide a secure, moisture-resistant environment for storing capsules, tablets, and powders. The non-reactive nature of certain plastics like HDPE is crucial for maintaining the integrity of sensitive pharmaceuticals.

- Industrial and Chemical: Used for storing paints, adhesives, lubricants, and various chemicals. Their durability and chemical resistance are key for these applications.

- Home and Garden: Employed for packaging items like plant foods, pesticides, and decorative items. Their robustness and moisture resistance are beneficial for outdoor or garage storage.

-

04 Environmental Impact and Sustainability of Plastic Jars

Plastic jars pose significant environmental challenges, but efforts are underway to mitigate their impact through various sustainable practices. Manufacturers are enhancing production efficiency to minimize waste and increasingly using post-consumer recycled materials to lessen reliance on virgin plastics. The industry is also focusing on improving the recyclability and reusability of jars, incorporating energy-efficient technologies in manufacturing processes, and adhering to strict environmental regulations. Additionally, educational campaigns and incentive programs are being launched to engage consumers in recycling efforts, collectively aiming to reduce the ecological footprint of plastic jars and promote environmental responsibility.

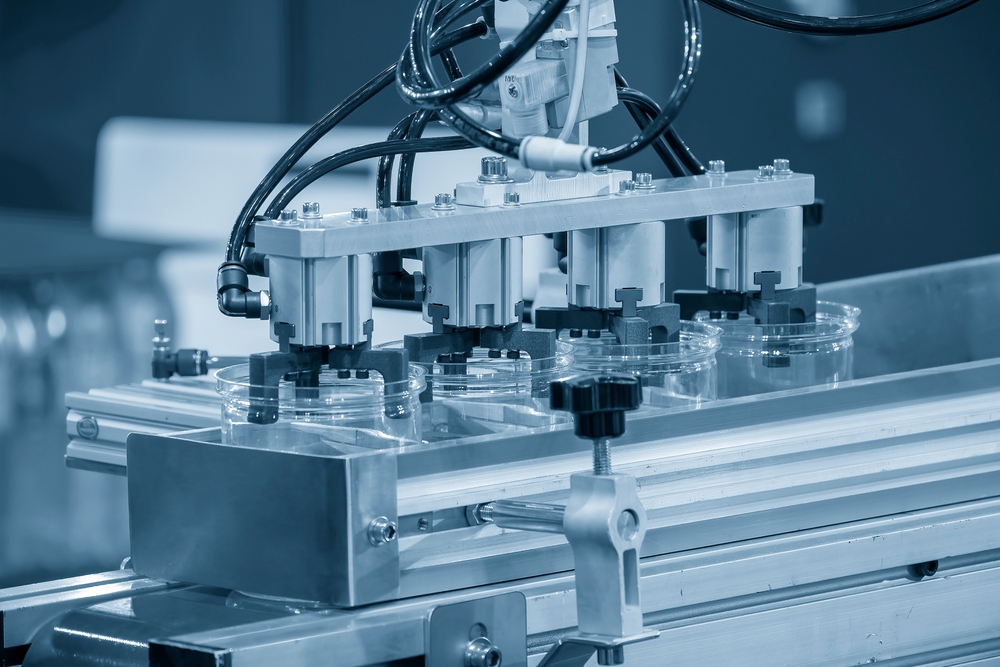

Your Gateway to Seamless Plastic Jars Solutions

CoPack Connect can connect brands with contract packagers that offer Plastic Jars Solutions. We make it easy for businesses to find the right manufacturer for their needs and provide the tools and resources they need to manage their shock-absorbing packaging projects successfully.

2000+

Manufacturers