Retorting Solutions that Create Competitive Advantage

Retorting is a thermal processing technique used primarily in the food industry to sterilize products packed in airtight containers, thereby significantly extending their shelf life while maintaining nutritional and sensory qualities. The process involves cooking food, sealing it in containers, and then heating those containers to high temperatures under pressure to destroy pathogens and spoilage organisms. This method is crucial for producing stable, shelf-stable products that do not require refrigeration.

Retorting remains a pivotal technology in food processing, pivotal for meeting the demands of modern food safety, distribution, and shelf stability. As technologies advance, the efficiency and application of retorting continue to expand, making it possible to process a broader range of products while minimizing nutrient loss and energy consumption.

-

01 How Retorting Works

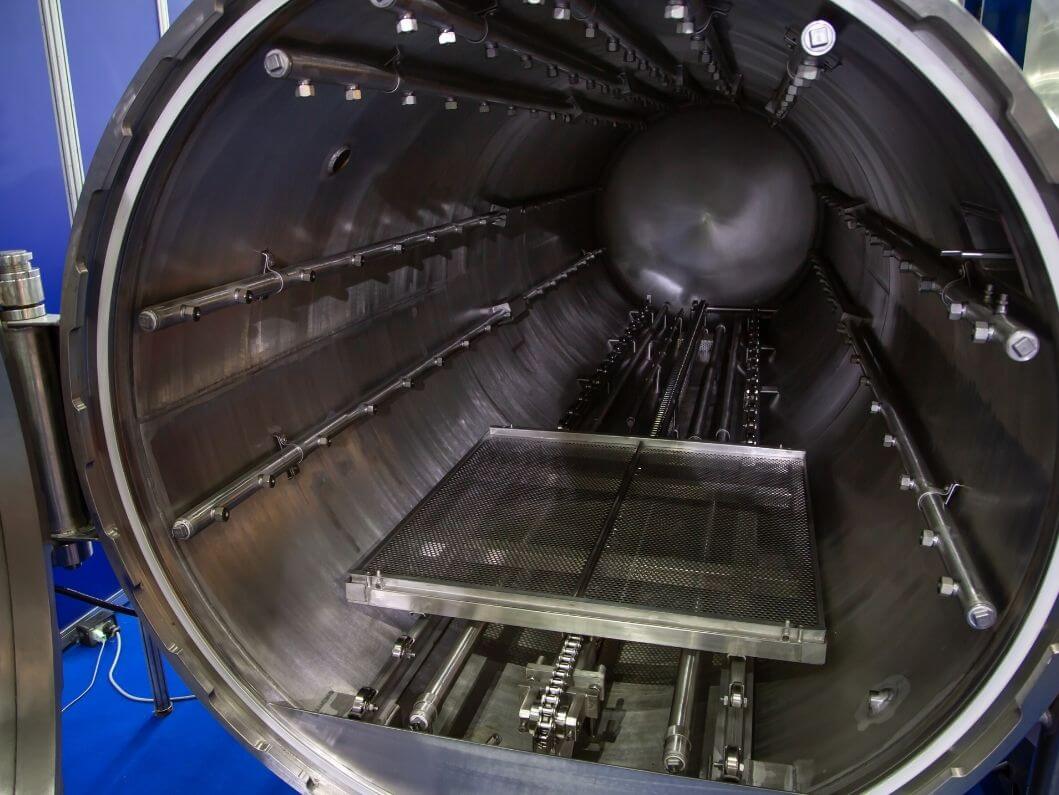

The retorting process begins with the placement of food products into containers, typically cans, jars, or flexible pouches. These containers are then sealed to prevent any external contamination. The filled and sealed containers are loaded into a retort—a large, pressure-resistant vessel—and subjected to high temperatures, generally between 110°C and 135°C, depending on the food type and the desired shelf life.

The heat is applied using steam, hot water, or in some advanced systems, a combination of steam and air (overpressure retorting). The application of heat and pressure ensures that any microorganisms present in the food are destroyed, making the food safe for long-term storage. Cooling follows the heating phase to prevent overcooking and to bring the temperature down to a level where it can be safely handled.

-

02 Retorting by Processing Type

- Batch Retorting: The traditional method where sealed containers are placed in a retort vessel, which is then closed, and the heating and cooling processes occur. Once the cycle is completed, the vessel is opened, and the containers are removed. This method is suitable for smaller production scales.

- Continuous Retorting: More suitable for large-scale production, this method involves moving the containers continuously through different chambers or zones in a tunnel-like retort. Each zone is dedicated to a particular phase of the process, such as heating, holding, and cooling. This type of retorting is more efficient and can handle higher volumes of product.

-

03 Benefits of Retorting

- Extended Shelf Life: Retorted products can be stored for long periods without refrigeration, which reduces logistics and storage costs.

- Safety: The process effectively eliminates harmful bacteria and other pathogens, ensuring food safety.

- Nutrient Retention: Although some nutrient loss can occur, retorting generally preserves more nutrients compared to other long-term preservation methods, such as canning.

- Versatility: A wide range of food products, from ready meals and vegetables to meats and seafood, can be processed using retorting.

-

04 Examples of Retorting Applications

- Canned Foods: This is the most common application of retorting, encompassing everything from canned vegetables and fruits to meats and complete ready-to-eat meals.

- Baby Foods: Due to their need for high levels of sterility and nutrient retention, baby foods are often processed using retorting.

- Pet Foods: Similar to human food applications, pet food benefits from the extended shelf life and safety provided by retorting.

- Ready Meals: Retort pouches are increasingly used for ready meals that require only reheating, combining convenience with safety and nutritional integrity.

Your Gateway to Seamless Retorting Solutions

CoPack Connect can connect brands with contract manufacturers and packagers that offer retorting services. We make it easy for businesses to find the right manufacturer for their needs and provide the tools and resources they need to manage their retorting projects successfully.

2000+

Manufacturers