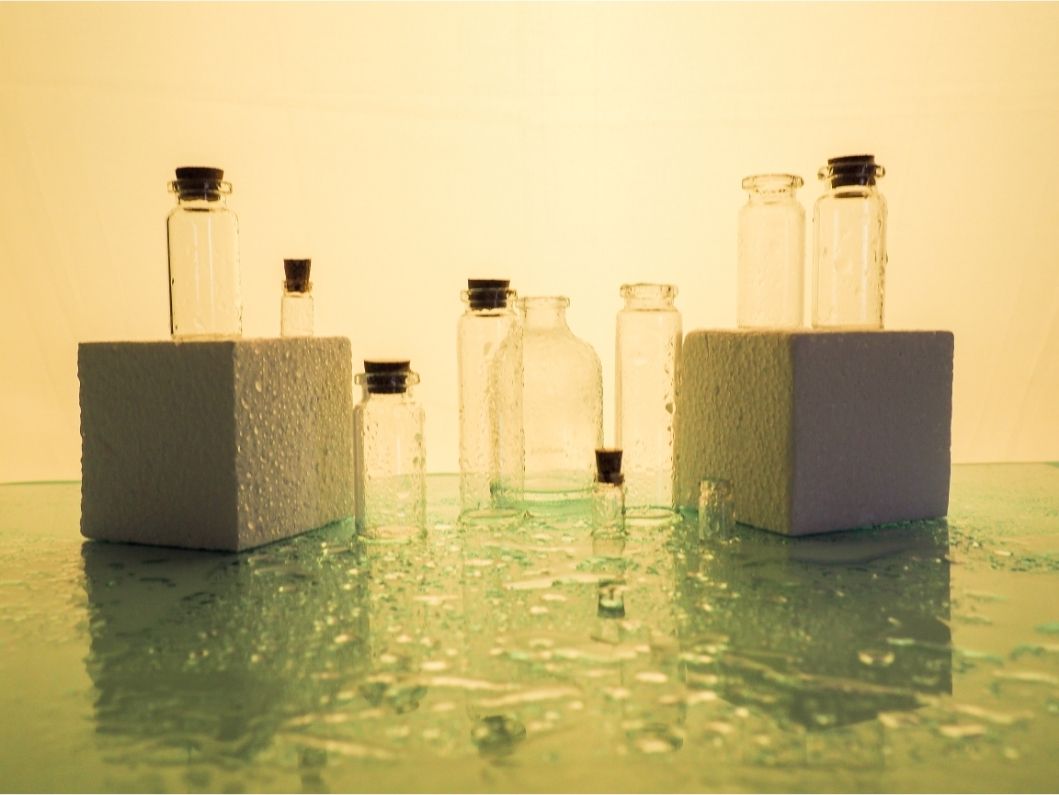

Transparent Bottles Solutions that Create Competitive Advantage

Transparent bottles have become a staple in the packaging world due to their ability to showcase the product inside while providing secure and durable containment. These bottles are available in a variety of shapes, sizes, and materials, making them suitable for a wide range of applications across different industries. From sleek, slender designs for beverages to robust containers for household cleaners, transparent bottles offer versatility and appeal. Their clarity not only highlights the product’s quality and color but also builds consumer trust by allowing a visual inspection before purchase.

-

01 Types of Transparent Bottles

- PET Bottles (Polyethylene Terephthalate): Lightweight and shatter-resistant, PET bottles are commonly used for water, soft drinks, and juices. They provide excellent clarity and are recyclable, making them a popular choice in the beverage industry.

- HDPE Bottles (High-Density Polyethylene): These bottles are more opaque but can be made transparent upon request. HDPE bottles are known for their strength and chemical resistance, making them ideal for storing household cleaners, detergents, and pharmaceuticals.

- Glass Bottles: Renowned for their superior transparency and ability to preserve the taste and quality of the contents, glass bottles are a premium choice for products like wine, spirits, gourmet sauces, and essential oils. They are recyclable and can be sterilized, adding to their appeal in the food and beverage sector.

- PP Bottles (Polypropylene): These are less clear but offer a good balance between transparency and durability. PP bottles are often used for syrups, condiments, and cosmetic products. They can withstand higher temperatures and are resistant to stress cracking.

- PVC Bottles (Polyvinyl Chloride): While not as widely used today due to environmental concerns, PVC bottles offer excellent transparency and are used for certain niche applications, like specialized chemical storage.

-

02 Features of Transparent Bottles

- Visibility: The most significant advantage of transparent bottles is their ability to showcase the product inside. This visibility helps attract customers by allowing them to see the product’s color, texture, and quality, fostering trust and enhancing appeal.

- Material Options: Available in various materials, including glass, PET, HDPE, and PP, transparent bottles cater to different needs—whether it’s for food safety, chemical resistance, or premium aesthetics.

- Customization: Transparent bottles can be customized in terms of shape, size, and closure types (such as screw caps, pump dispensers, or flip-tops) to suit specific product requirements. This flexibility extends to the design and labeling options, allowing brands to add a personal touch with unique branding and product information.

- Durability: Depending on the material, transparent bottles offer varying levels of durability. Glass provides a classic, high-end feel but is heavier and more prone to breakage. Plastics like PET and HDPE offer lightweight durability, making them ideal for products requiring frequent handling or transport.

- Recyclability: Many transparent bottles, especially those made from PET, glass, and some HDPE formulations, are recyclable. This makes them a sustainable option for businesses aiming to reduce their environmental footprint.

-

03 Benefits of Transparent Bottles

- Consumer Appeal: The transparency of these bottles gives consumers confidence in their purchase by allowing them to visually assess the product. This is especially important for items like beverages, oils, and sauces where the appearance is closely tied to perceived freshness and quality.

- Versatility: Transparent bottles are suitable for a wide array of products, from food and beverages to personal care items and household chemicals. This versatility makes them a go-to packaging solution across multiple industries.

- Product Protection: While showcasing the product, transparent bottles also protect it from external elements. Depending on the material used, they offer excellent barriers against moisture, oxygen, and contaminants, preserving product integrity.

- Ease of Use: Many transparent bottles are designed with user-friendly features such as ergonomic shapes for easy handling, precise pouring spouts, and secure closures to prevent leaks and spills.

- Cost-Efficiency: Transparent plastic bottles, in particular, are cost-effective to produce and transport. Their lightweight nature reduces shipping costs and their durability lowers the chances of damage during transit, contributing to overall cost savings.

-

04 Different Uses of Transparent Bottles

- Food and Beverage Industry: Widely used for packaging water, juices, sauces, oils, and dressings. Transparent bottles enhance shelf appeal and allow consumers to see the product’s freshness and quality.

- Personal Care: Ideal for shampoos, conditioners, lotions, and body washes. The clarity of the bottle adds to the visual appeal of the product, particularly when the contents have vibrant colors or unique textures.

- Pharmaceuticals: Used for liquid medications, syrups, and supplements. Transparency ensures easy identification and monitoring of the product level, enhancing user convenience and safety.

- Household and Industrial: Suitable for detergents, cleaners, and automotive fluids. Their robustness and chemical resistance make them a practical choice for storing various liquid and gel formulations.

- Cosmetics: Frequently used for serums, toners, and other skincare products. The sleek and clear design of the bottles adds a premium feel, attracting consumers looking for high-end beauty solutions.

-

05 Environmental Impact and Sustainability of Transparent Bottles

The sustainability of transparent bottles largely depends on the material chosen. PET and glass are leading the way in recyclability, with PET being the most recycled plastic worldwide. The manufacturing process for PET bottles has also become more efficient, using less energy and water. Similarly, glass bottles, although energy-intensive to produce, can be infinitely recycled without loss of quality, making them a sustainable option in the long term.

Your Gateway to Transparent Bottles Solutions

CoPack Connect can connect brands with contract packagers that offer transparent bottles packaging services. We make it easy for businesses to find the right manufacturer for their needs and provide the tools and resources they need to manage their polycarbonate bottle packaging projects successfully.

2000+

Manufacturers