Topping Food Processing Type

Topping is a crucial process in various industrial and manufacturing sectors, particularly in the context of chemical processing, where it involves the selective removal or separation of specific components from a mixture. This process is widely applicable in industries such as petrochemicals, food processing, and metallurgy, among others.

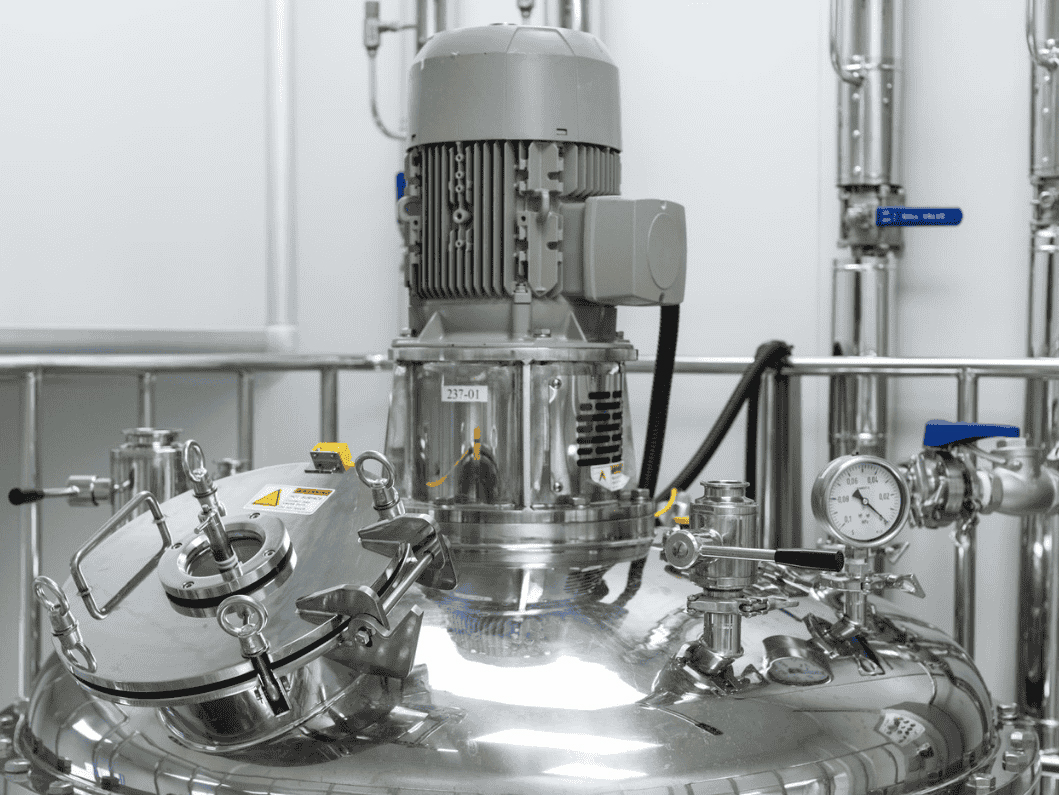

Topping primarily involves the separation of components within a mixture, and its specific mechanism depends on the application. In oil refining, for instance, topping is performed using a distillation process. Here, crude oil is heated in a distillation column, causing different hydrocarbon components to vaporize at varying temperatures due to their distinct boiling points. Lighter fractions like gasoline and naphtha vaporize first and rise higher in the column, where they condense back into liquids at different levels, allowing for their separate collection. In other industries, topping may employ mechanical methods such as filtration or centrifugation, where physical barriers or forces separate substances based on size, weight, or density.

Additionally, membrane technologies are used to achieve separation at a molecular level, where semi-permeable materials allow specific molecules to pass through, effectively separating them from others in the mixture. Each of these methods tailors the process of topping to suit the desired purity, efficiency, and safety required in different industrial applications.

-

01 Topping by Processing Type

- Chemical Engineering (Oil Refining): In oil refining, topping refers to the initial distillation process used to separate crude oil into various components. The process uses a distillation column where heated crude oil is fed. As the oil heats up, it vaporizes, and different components with varying boiling points separate. Lighter fractions like gasoline and naphtha rise and condense at higher points in the column, while heavier fractions remain lower or come out as residuals.

- Other Applications: In applications beyond oil refining, topping can involve filtration, centrifugation, or membrane technologies, depending on the mixture and desired outcome.

These methods focus on separating solids from liquids, or from finer particles in suspension, achieving the desired concentration or purity levels.

-

02 Benefits of Topping

- Enhanced Product Purity and Quality: Topping removes undesired components or impurities, ensuring that the final products meet specific standards and are suitable for their intended use.

- Optimization of Resource Use: By extracting valuable components efficiently and minimizing waste, topping improves economic efficiency and reduces environmental impact.

Your Gateway to Seamless Topping Solutions

CoPack Connect can connect brands with contract manufacturers and packagers that offer topping services. We make it easy for businesses to find the right manufacturer for their needs and provide the tools and resources they need to manage their relabeling projects successfully.

2000+

Manufacturers