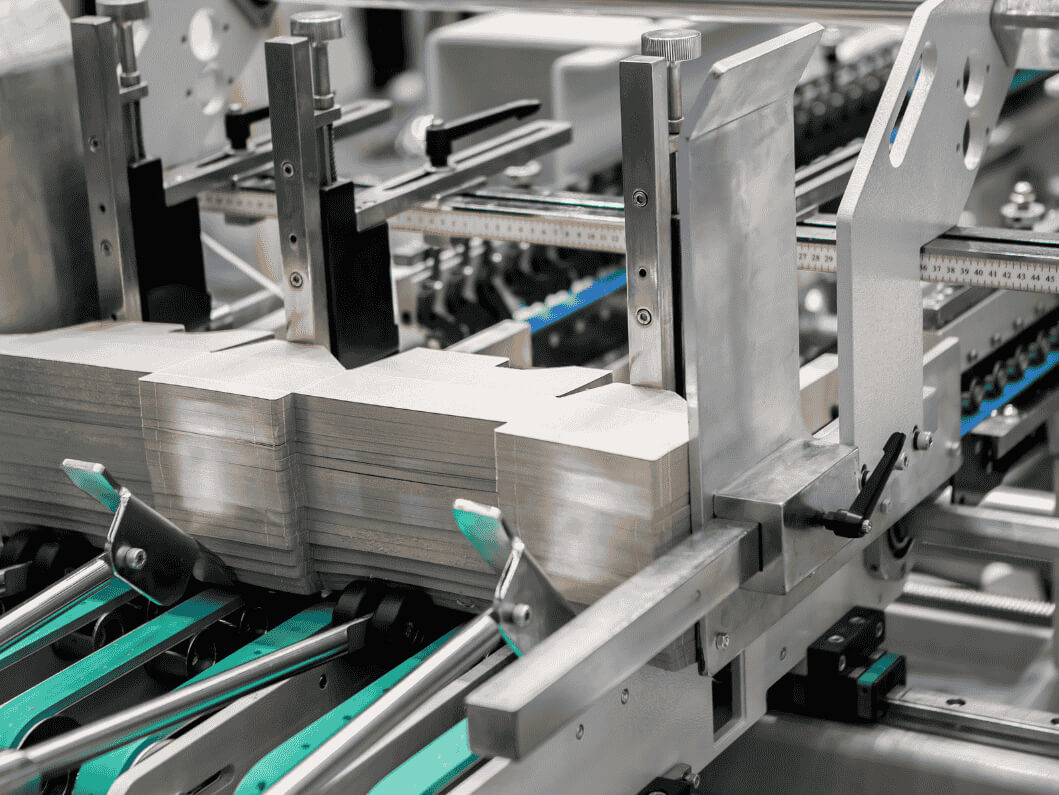

Gluing Secondary Packaging

Gluing, in the context of materials processing and manufacturing, is the method of joining two or more materials together using adhesives. Adhesives are substances that can bind materials together and resist separation. The gluing process typically involves the application of an adhesive to at least one of the surfaces to be joined, followed by the mating of these surfaces and the application of pressure to facilitate the bond.

-

01 Gluing by Processing Type

Gluing can be categorized based on the type of adhesive used and the process through which bonding is achieved. Here are some common types:

- Hot Melt Gluing – This involves adhesives that are applied in a molten state and quickly set by cooling. Commonly used for packaging and in industries where quick setting is essential.

- Cold Gluing – Adhesives used here are applied at room temperature and may require time to set through evaporation of a solvent or curing by chemical reactions. This method is often used in woodworking and paper processing.

- Reactive Gluing – These adhesives undergo a chemical reaction when applied, which forms a strong bond. Epoxies used in construction and automotive industries are a typical example.

- Pressure-sensitive Gluing – These adhesives are permanently tacky and adhere to surfaces on contact with light pressure. They are widely used in labels and notes like Post-Its.

-

02 Benefits of Gluing in Processing

Gluing offers several advantages across various industries, making it a preferred method of bonding:

- Versatility: Adhesives can join a wide array of materials including metals, plastics, glass, and wood, providing flexibility in manufacturing processes.

- Distribution of Stress: Unlike mechanical fastening, gluing distributes stress more evenly across the joint, reducing the concentration at any single point and enhancing the joint’s overall strength.

- Aesthetics: Gluing can be performed without altering the surface appearance, making it ideal for applications where a clean and smooth appearance is desirable.

- Cost-Effectiveness: It often requires less labor and lower operational costs compared to welding or mechanical fastening.

- Ease of Automation: Gluing processes can be easily automated, improving production efficiency and consistency in large-scale manufacturing.

- Thermal and Acoustic Insulation: Certain adhesives provide beneficial properties such as insulation against heat or sound, adding functional value beyond just bonding.

-

03 Examples of Gluing Application

Gluing finds applications in a multitude of industries and products, showcasing its versatility and effectiveness:

- Aerospace: Used to bond structural components of aircraft and spacecraft where welding might compromise material integrity.

- Automotive: Glues are used to attach glass, interiors, panels, and even in lightweighting efforts to reduce vehicle weight.

- Electronics: Adhesives are used to assemble components such as screens, batteries, and casings in devices like smartphones and laptops.

- Construction: Gluing is essential for attaching panels, flooring, and fixtures, as well as in structural reinforcements.

- Medical Devices: Specialized adhesives are used in the manufacturing of devices that require sterile conditions and biocompatibility.

- Packaging: Hot melt adhesives are extensively used for box sealing, carton closing, and other packaging applications.

Your Gateway to Seamless Gluing Solutions

CoPack Connect can connect brands with contract manufacturers and packagers that offer gluing services. We make it easy for businesses to find the right manufacturer for their needs and provide the tools and resources they need to manage their relabeling projects successfully.

2000+

Manufacturers