Manual Assembly Secondary Packaging

Manual assembly is a fundamental method in manufacturing where components are assembled to form a product primarily by human operators, rather than by automated systems or robotic mechanisms. This traditional approach relies on the skills, dexterity, and decision-making capabilities of human workers to perform complex or delicate tasks that are difficult to automate.

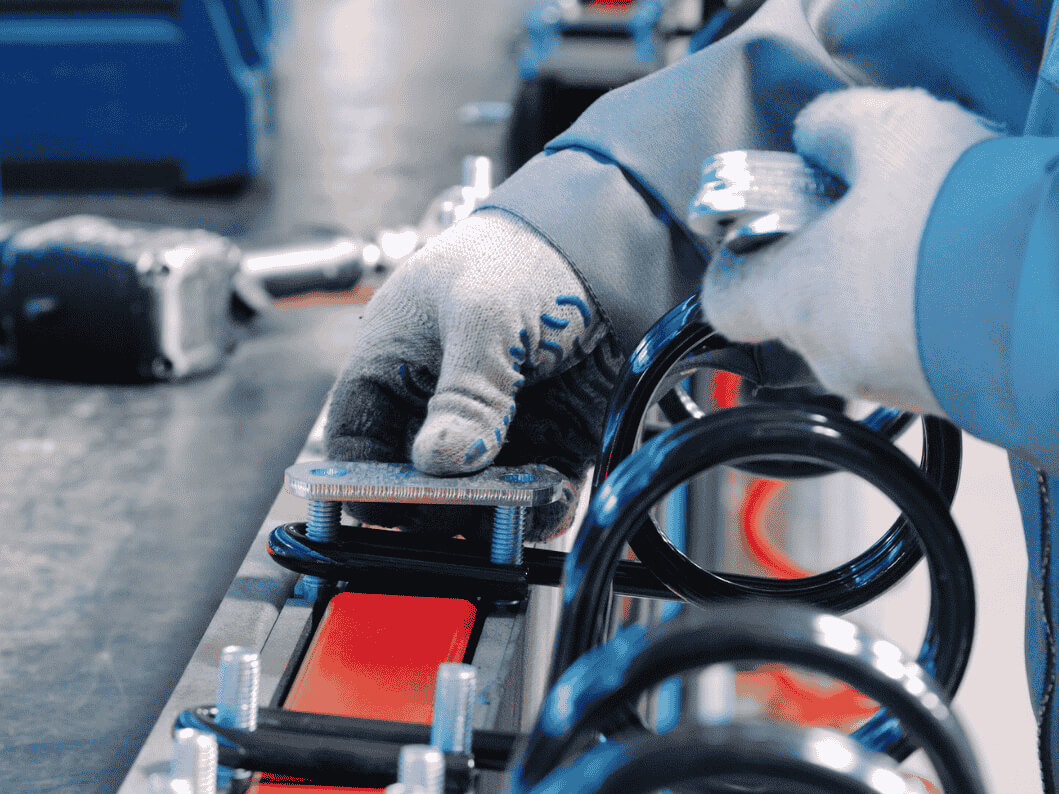

Manual assembly involves several stages, starting with the preparation of individual parts. Workers at assembly stations use tools and fixtures to join parts together, often following detailed instructions or blueprints. The process can include fitting, screwing, soldering, and using adhesives to ensure that components are assembled accurately and securely. Throughout the assembly, quality control is maintained through visual inspections and manual testing by the workers or dedicated inspectors.

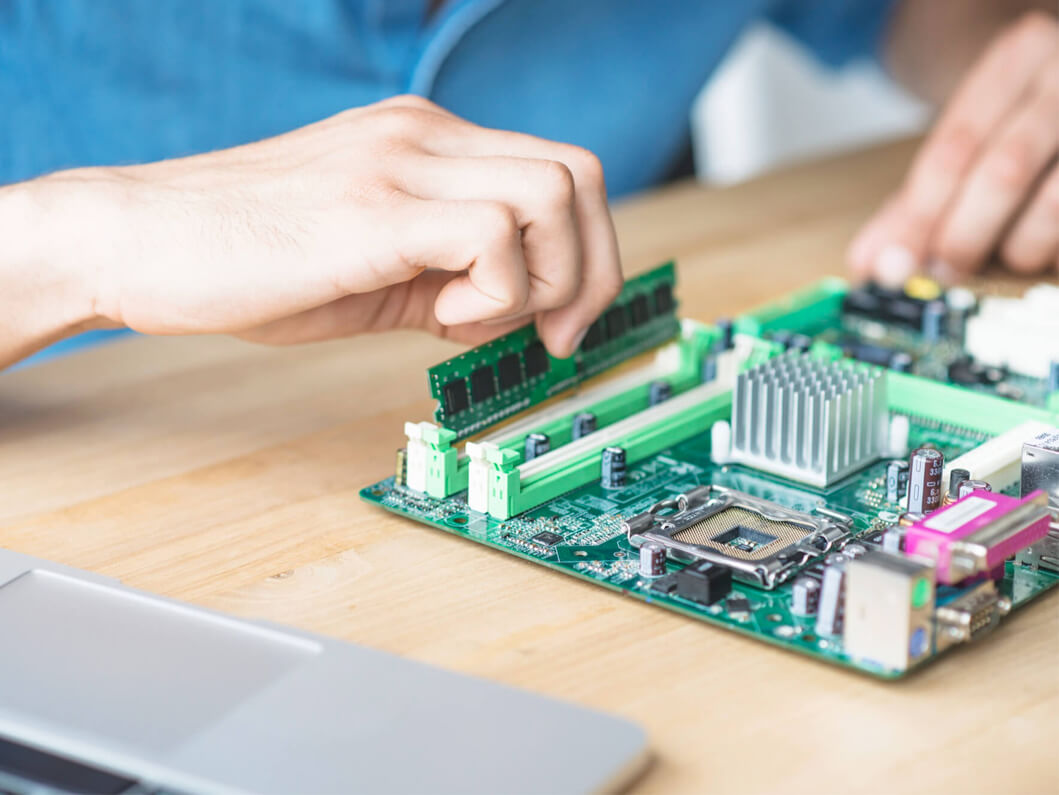

The specific steps in manual assembly vary widely depending on the product being manufactured. For example, assembling an electronic device might require careful handling of sensitive components and precise soldering of small parts, while furniture assembly might focus more on the physical alignment and securing of larger wooden or metal pieces.

-

01 Manual Assembly by Processing Type

Manual assembly can be categorized into different types based on the processing approach:

- Batch Assembly: In this type, components are assembled in batches. Each batch goes through one stage of the process before moving on to the next, allowing workers to specialize in specific tasks. This can enhance efficiency and quality in scenarios where large volumes of similar products are produced.

- Line Assembly: Often used in mass production, this method involves setting up an assembly line where each worker or group of workers is responsible for one specific task. As the product moves along the line, it gradually comes together. This method is highly structured and can lead to significant increases in speed and consistency.

- Cellular Assembly: This approach organizes the assembly space into cells, each capable of completing an entire product or a major subsection of a product. It allows for more flexibility in adjusting to changes in product design or demand.

-

02 Benefits of Manual Assembly in Processing

Manual assembly offers several advantages, particularly in certain industries and scenarios:

- Flexibility: Human workers can quickly adapt to changes in product designs or correct errors on the fly, making manual assembly ideal for custom products or small production runs.

- Quality: Skilled workers are often better at achieving high-quality finishes and at noticing minor defects that machines might miss, which is crucial in industries where precision is vital, such as aerospace and luxury goods.

- Cost-effectiveness: For small-scale production, manual assembly can be more cost-effective than investing in specialized machinery or automation technology, which might require significant upfront costs and maintenance.

- Employment: Manual assembly provides jobs that require a range of skills and levels of expertise, contributing to employment opportunities.

-

03 Examples of Manual Assembly Applications

Manual assembly is employed across various industries, demonstrating its versatility and importance:

- Electronics: Assembling devices like smartphones and laptops often involves manual processes to connect delicate components like microchips and cables.

- Automotive: While much of the automotive assembly is automated, intricate tasks like installing certain interior components or performing final quality checks are often done manually.

- Furniture: Many furniture items are still assembled manually, especially those that require custom designs or have intricate details.

- Jewelry and Watches: High-end watches and jewelry often rely on the skilled hands of craftspeople to assemble tiny, precise components.

Your Gateway to Seamless Manual Assembly Solutions

CoPack Connect can connect brands with contract manufacturers and packagers that offer manual assembly services. We make it easy for businesses to find the right manufacturer for their needs and provide the tools and resources they need to manage their relabeling projects successfully.

2000+

Manufacturers